Ransomware Attacks in Manufacturing Doubled From 2019

From 2019 to 2021, ransomware attacks in manufacturing doubled, making it the most commonly targeted industry in 2020 and 2021, according to Advisen loss data. Advisen’s loss database contains 3,415 ransomware attacks and 189 ransomware attacks in manufacturing.

The manufacturing industry is a high-value target for ransomware attacks. Most manufacturers have embraced automation and digitization, but many only store files locally, leaving them vulnerable to attack.

Manufacturing companies also store high-value data, such as intellectual property and trade secrets, which makes manufacturers more likely to pay if their information is stolen or hackers threaten to publish it online. In some cases, hackers will steal data involving third parties as well, such as clients, suppliers and partners. This gives them even more leverage to extort money in a ransomware attack.

In addition to ransom payments, ransomware attacks on manufacturing can also be extremely costly in terms of response and business interruption costs. For example, the ransomware attack on meat supplier JBS Foods on May 31, 2021, resulted in a total shutdown of operations and an $11 million ransom, according to Advisen loss data.

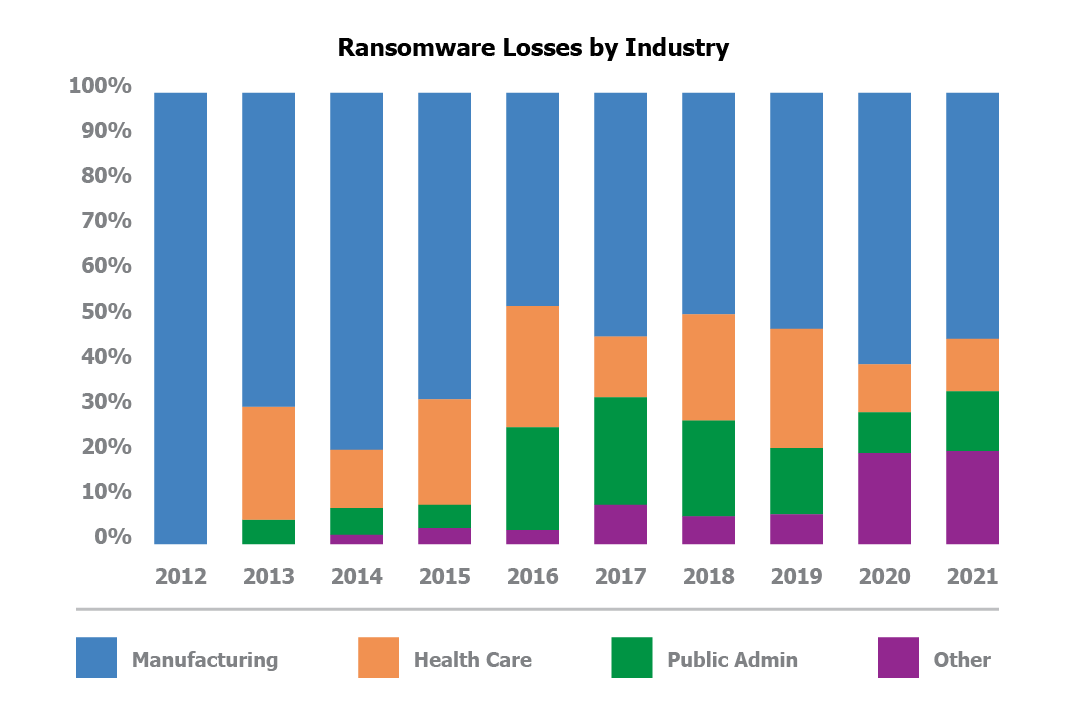

Looking at ransomware losses by industry over time, public administration and health care were some of the most frequently targeted industries from 2013 to 2019; manufacturing accounted for a relatively small percentage of total ransomware attacks. However, by 2020, manufacturing became the most commonly targeted industry.

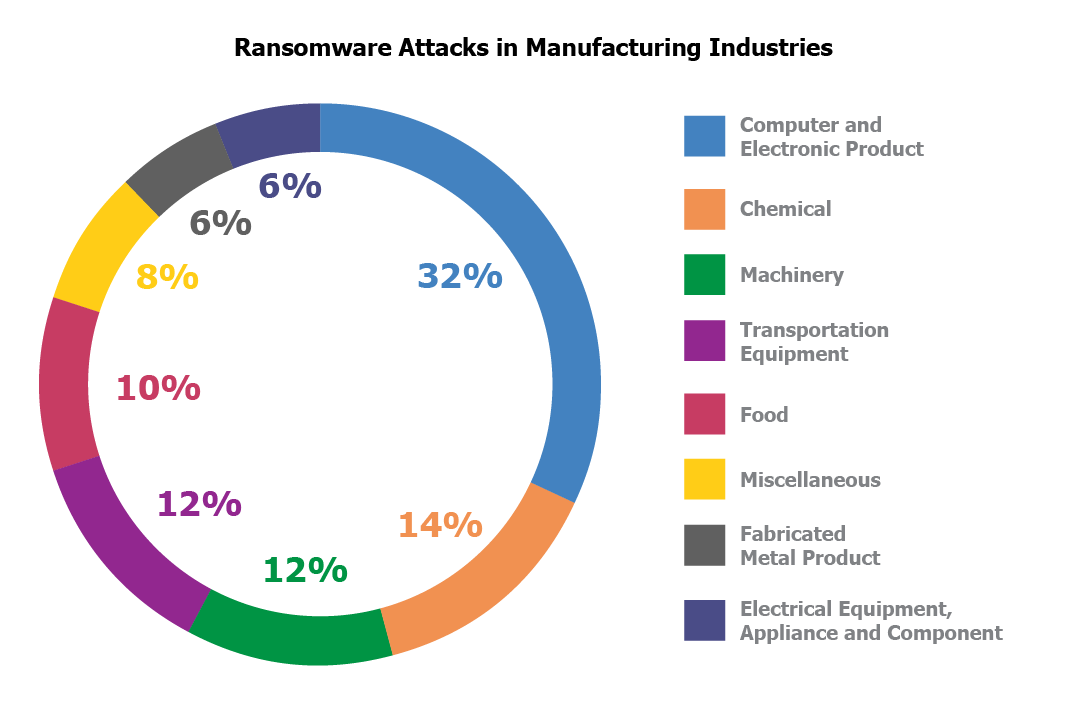

Within the manufacturing industry, computer and electronic product manufacturing saw nearly double the number of ransomware attacks than any other category at 32%. These attacks include ransomware attacks on an Apple supplier, Samsung Electronics and Bose Corporation, according to Advisen loss data.

Chemical manufacturing accounted for 14% of the remaining losses, while machinery manufacturing and transportation equipment manufacturing each accounted for 12%, according to Advisen loss data.

Contact INSURICA today to learn more about our manufacturing industry services and capabilities.

© 2022 Zywave, Inc. All rights reserved.

About the Author

Share This Story

Related Blogs

Insurers Turn to Telematics to Address Rising Commercial Auto Losses

Amid a steep rise in accident severity and litigation costs, commercial auto insurers are turning to telematics technology to improve risk assessment and help stabilize a market under financial strain.

Workers’ Compensation: Avoiding the Most Common School Staff Injuries

School districts work hard to keep students safe, but [...]

Marketplace Coverage and Employer Plans: What Employers Need to Know

As Marketplace health plan premiums rise and subsidies shift, employers are seeing more requests from employees (and their spouses) to drop Marketplace coverage and enroll in an employer-sponsored health plan mid-year. While this may feel straightforward, Marketplace rules and employer plan rules do not always work the same way.